Strong and flexible with high esthetic standards

The edelweiss SYSTEMS are manufactured by combining three dental technologies in a single material, utilising the advantages of each system and fusing them into a highly esthetic material, resulting in high strength (560 MPa) and flexibility (20 GPa).

The material consists of a combination of pure glass ceramic, particle-filled ceramic and carbon technology in one block. The combination utilises the excellent esthetics and compressive strength without the brittleness and hardness. A small amount of carbon is added to the material to achieve elasticity and thus a bio-mimetic property. The flexibility corresponds to dentine and the hardness to enamel, while zinc oxide nanoparticles provide antibacterial properties.

This material belongs to a new generation of ceramics, namely bio-mechanical glass-ceramics. It is produced using a patented laser process in which the glass crystals are sintered and vitrified. The finished bio-ceramic edelweiss CAD/CAM BLOCK is thus characterised by a homoge-neous glass-ceramic phase embedded in a carbon matrix. As it is an inorganic, crystalline bioceramic glass phase, the material offers the advantage of biomimetic mechanics, a bio-esthetic appearance and bio-compatibility, as it is completely free of BIS GMA, BIS EMA and UDMA.

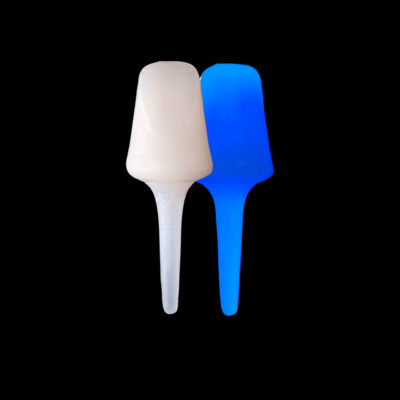

Innovation inspired by nature – Bio-ceramic edelweiss CAD/CAM BLOCKs

The laser-sintered and vitrified edelweiss CAD/CAM BLOCKs have similar esthetic properties to feldspatic glass-ceramics, but are not as brittle and hard as pure ceramics and zirconia. The strength is similar to ceramic, but they retain the flexibility of hybrid materials.

Features and benefits

- Esthetically pleasing, lifelike appearance combined with high strength (560 MPa compressive strength)

- Bio-mimetic (20 GPa modulus of flexibility) and bisphenol A free

- Laser sintered and vitrified, no additional firing required, quick polishing with a goat hair brush only and easy cementation

- Cost savings through faster processing and up to 3 x longer service life of CAD/CAM milling drill as well as energy efficiency